CIAK STARTER TECHNOLOGY

CIAK STARTER with its CIAK STARTER line, the company C.I.A.K. has been the innovative leader in the battery offer for 20 years. We are the leaders in introducing on the market batteries that do not require any additional and subsequent maintenance after installation on your vehicle. Then the pioneer of the technology, today this is the part of the standard offer of the most serious battery manufacturers. It was then that the company C.I.A.K., with its visionary view on the future, brought innovative technology to their vehicles with the perfect value for money.

CIAK STARTER, in all battery models for personal vehicles programme, is made completely with the technology that does not require any maintenance after installation on the vehicle (Maintenance Free). Besides, all CIAK STARTER batteries satisfy 99% of manufactured vehicles in the world, with their capacity, starting power delivery, as well as with dimensions. That is why the label on every CIAK STARTER battery – MATCHING O.E. QUALITY (identical to the originally installed) really lives up to its words.

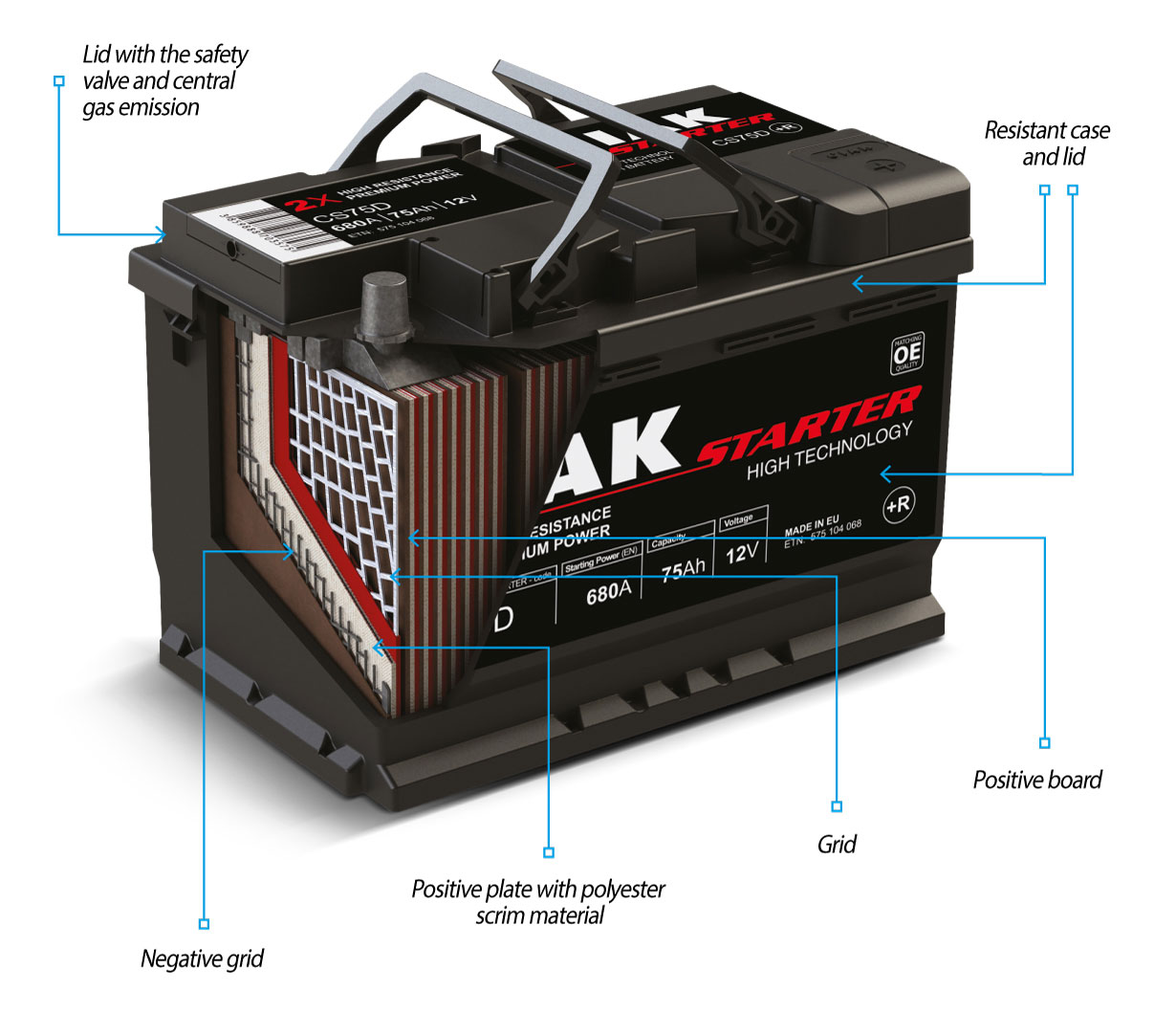

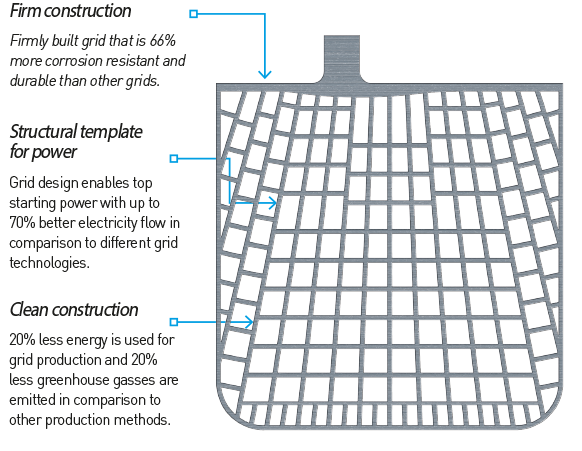

Grid

The most innovative part of any CIAK STARTER battery. It is specially designed for the prefect electricity flow thus enabling low resistance and top conductivity. The technology that enables CIAK STARTER battery with the faster charging and easier energy reception in extreme use. In the moments of the biggest demand for starting your vehicle, CIAK STARTER has the highest values of cold start electricity regardless of the capacity. The grid installed in every CIAK STARTER battery is 66% firmer than any battery from the competition and is more corrosion resistant. Many batteries on the market are still manufactured with the outdated technology of grid production which can cause earlier damage or not optimal energy source at any moment of use. CIAK STARTER uses grid technology that, at any time of use, without impact on external conditions or timeline it is used at, always provides the maximum and same product specifications.

GLOSSARY

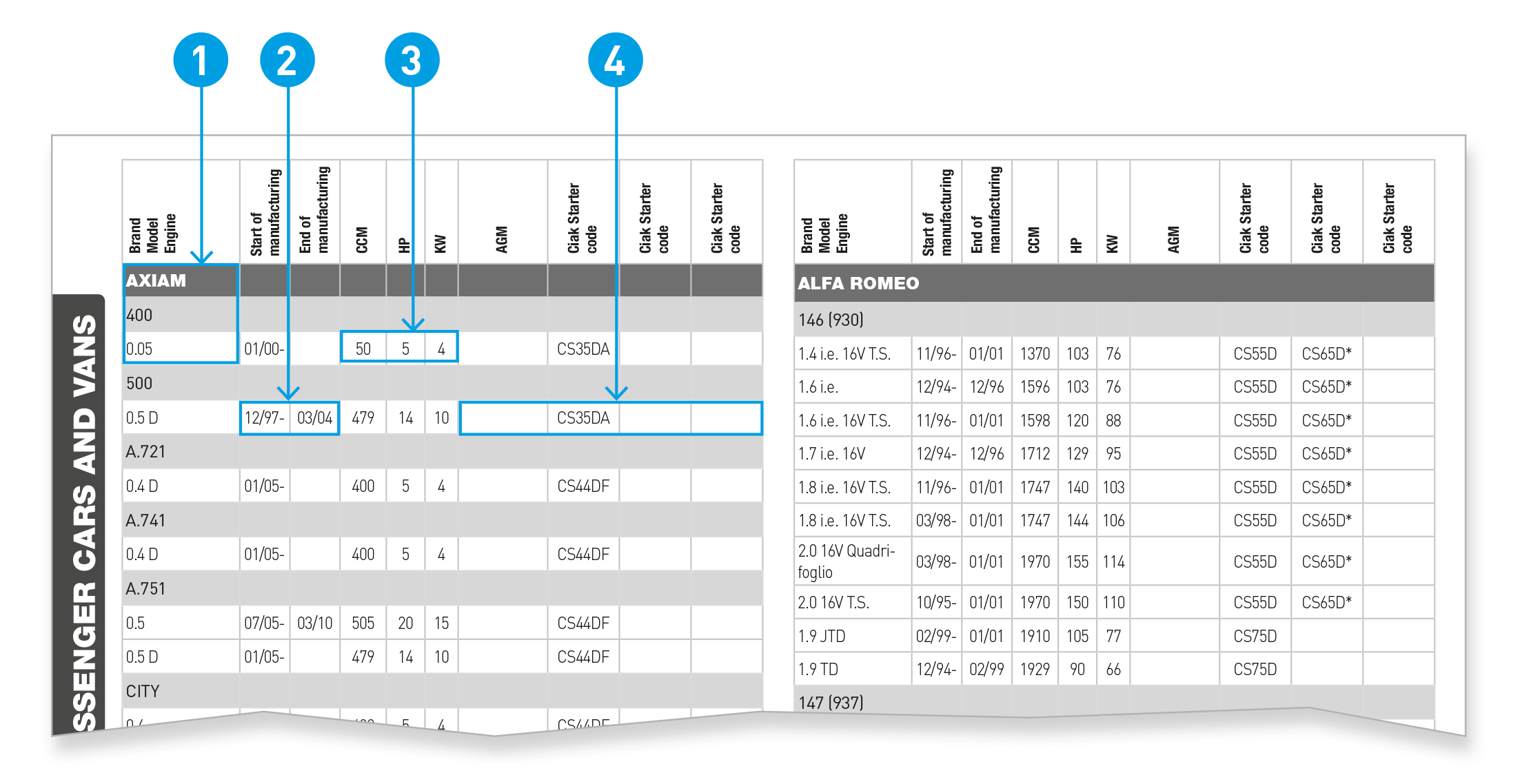

Meaning of markings

- Vehicle manufacturer, model and type (listed from A to Z)

- Date of manufacture from / to

- Engine capacity / number of horse power / number of kilowatts

- CIAK starter code

- Cold start power

- Amperage

- Voltage

- ETN code

- Line of CIAK products

BATTERY INSPECTION

A Visual inspection

A1 Is the battery leaking?

Move to A2.

Batteries with caps: move to B.

Batteries without caps: move to D.

A2 Are the areas of impact, thrust and pressure visible in the leaking area?

No claim rights. Check the surface of the battery glass for e.g. erroneous tension, foreign objects on the surface of the battery glass.

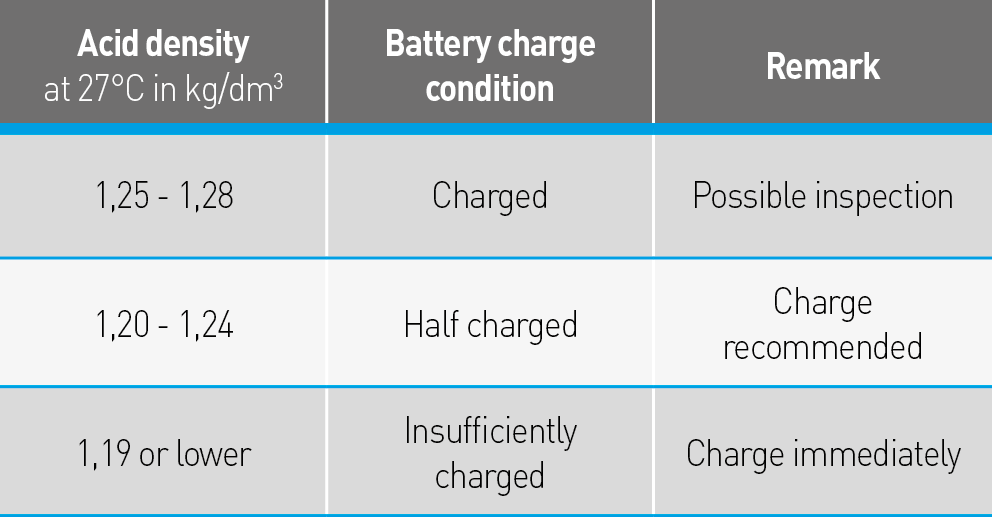

B Check acid density

Acid density of a good battery must be equal in all columns. Follow the instructions on charger and battery use during charging.

B1 Did the charging density suddenly fall in one of the columns?

Maximum allowed tolerance to the difference of measuring values within 6 columns is: 0,03 kg/dm3.

Replace battery. *

Move to B2.

B2 Is the acid brownish and is increased water consumption present?

No claim rights.

(Check the voltage regulator on the vehicle and capacity loads).

Move to B3.

B3 Is the density of acid equal in all columns and over 1.25kg / dm3?

Move to C or D.

Charge the battery, move to B4.

B4 If the acid density is equal in all columns >1,24 kg/dm3, charge the battery. Does the voltage consumption equal to at least 1/20 of the capacity? (example: 100 Ah battery: 100 Ah x 1/20 = 5A)

Charge the battery and move to C or D.

If charging results in final acid density of 1,24 kg/dm3 or lower, there are no grounds for claim, because of the regular wear due to old age.

– No claim rights.

No claim rights.

Battery is damaged due to insufficient charging, i.e. deep charging. Check the vehicle electrics (voltage regulator, lighting, straps, etc.).

C Discharge inspection

This inspection should be done if the acid density is even and shows the lowest density of 1,25 kg/dm3, otherwise the battery should be charged first.

Note: Pay attention to instructions for battery inspection use.

C1 Does the battery show “Broken” or “Replacement” during

high-voltage inspection?

Replace battery

Battery is orderly

For the inspection of loads with attached resistors: Battery is loaded for 10 seconds with approximately tertiary value of the rated capacity (e.g. battery 12 V 45 Ah corresponds to the approximately 135 A of voltage load). During this procedure, voltage can only be slightly changed.

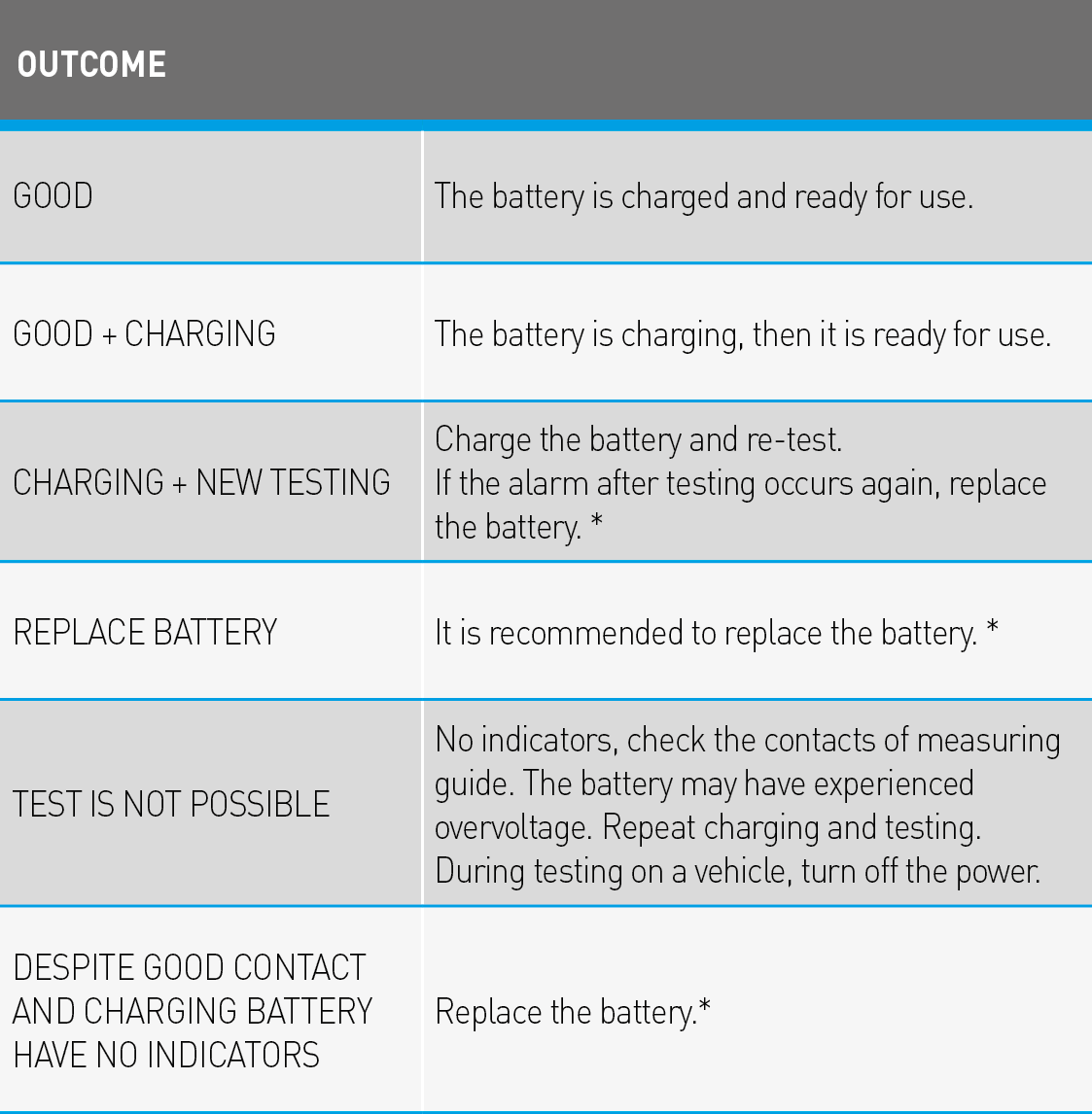

D Battery testing with electronic testing apparatus

Follow instructions for the use of testing apparatus

Cold testing voltage, known as cold ignition voltage or CCA (Cold Cranking Amps), goes together with the set norm on the battery.

NOTE

If the cold testing voltage is unknown: for starting battery:

5 x K20 = Cold testing voltage e.g. K20 = 100 Ah: voltage is 5x 100 = 500 A; for ignition and lighting battery (esp. GEL): 3 x K5 cc. possible cold voltage.

If the apparatus has only one option for adjustment according to the old DIN-norm, DIN-voltage is calculated from EN-voltage: DIN-voltage = EN-voltage x 0,6.

With temperatures below 0C temperature, compensation must be taken into consideration.

For testing apparatus in general:

Testing programme calculates phrases “good” or “replacement” on the basis of charging state and available starting performance. It can happen that the battery with 45% of starting performance shows “good” and other with 75% of starting performance shows “replace”. Starting performance comes from the amount of calculated and inserted cold testing voltage; it can exceed 100%.

Electronic testing apparatus is appropriate for batteries used for a certain period of time only and cannot test the performance of new or unused batteries.

Due to this fact, CIAK recommends the implementation of established testing for rated data in EN 50342 testing.

* Claims according to the valid regulations on handling and warranty conditions.

WARRANTY DOES NOT INCLUDE:

* regular wearing

* not following instructions for use

* reckless and unprofessional assembling, load or handling

* adding of the so-called improvement agents

We are specially addressing the fact that the estimated life cycle depends on the time of use, temperature and battery application. Evaluation of “claim rights” is always implemented in accordance to the above mentioned.

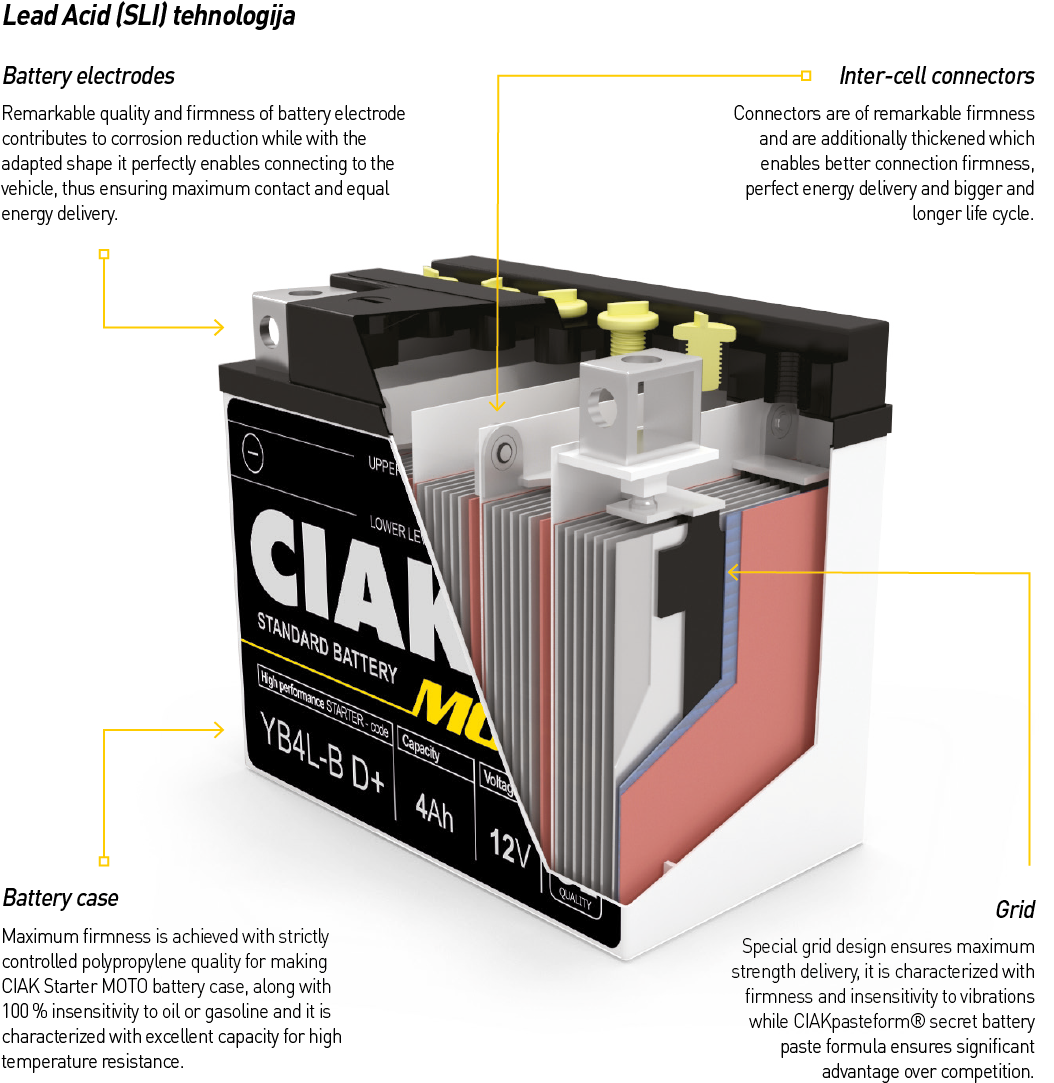

CIAK STARTER MOTO TECHNOLOGY

CIAK STARTER MOTO

CIAK STARTER MOTO – TRADITIONAL AND TESTED TECHNOLOGY

Best-selling and most frequently chosen moto battery is CIAK STARTER MOTO. It is a traditional product with tested liquid electrolyte technology, also known as – battery requiring maintenance. It is the holder of reliability epithet and ideal energy supplier at any moment and in any situation. It is tested in the most extreme conditions, used in various vehicles of the type and it consistently delivers remarkable strength. CIAK STARTER MOTO batteries have 33 models and you can be sure that among them is the one that will completely satisfy your needs for this type of alternative energy source, for your motorcycle, as well as for the scooter, ATV or any other similar vehicle.

CHARGING CIAK STARTER MOTO BATTERY REQUIRING MAINTENANCE

Remove the caps

It is necessary to remove all caps from the battery lid by screwing or with a simple pull – you have to keep them for later use.

Remove the valve lid

Remove the outlet valve lid before charging with electrolyte.

Prepare bottle with acid

Cut out the top of the nozzle and be careful so that you keep part of the nozzle body (cca 10 mm) in order to put the charging tube on it.

Place the tube on the nozzle

Push the tube to the maximum on the remaining part of the nozzle so that the electrolyte would not leak on the sides during charging.

Charge the battery with electrolyte

Carefully pour electrolyte into every chamber of the battery and pay attention that they are equally full up to the “max” marker found on the sticker.

Place the caps

Put back original battery caps in each opening at the same time attending that every cap is pushed in the opening to the maximum in order to prevent electrolyte leakage.

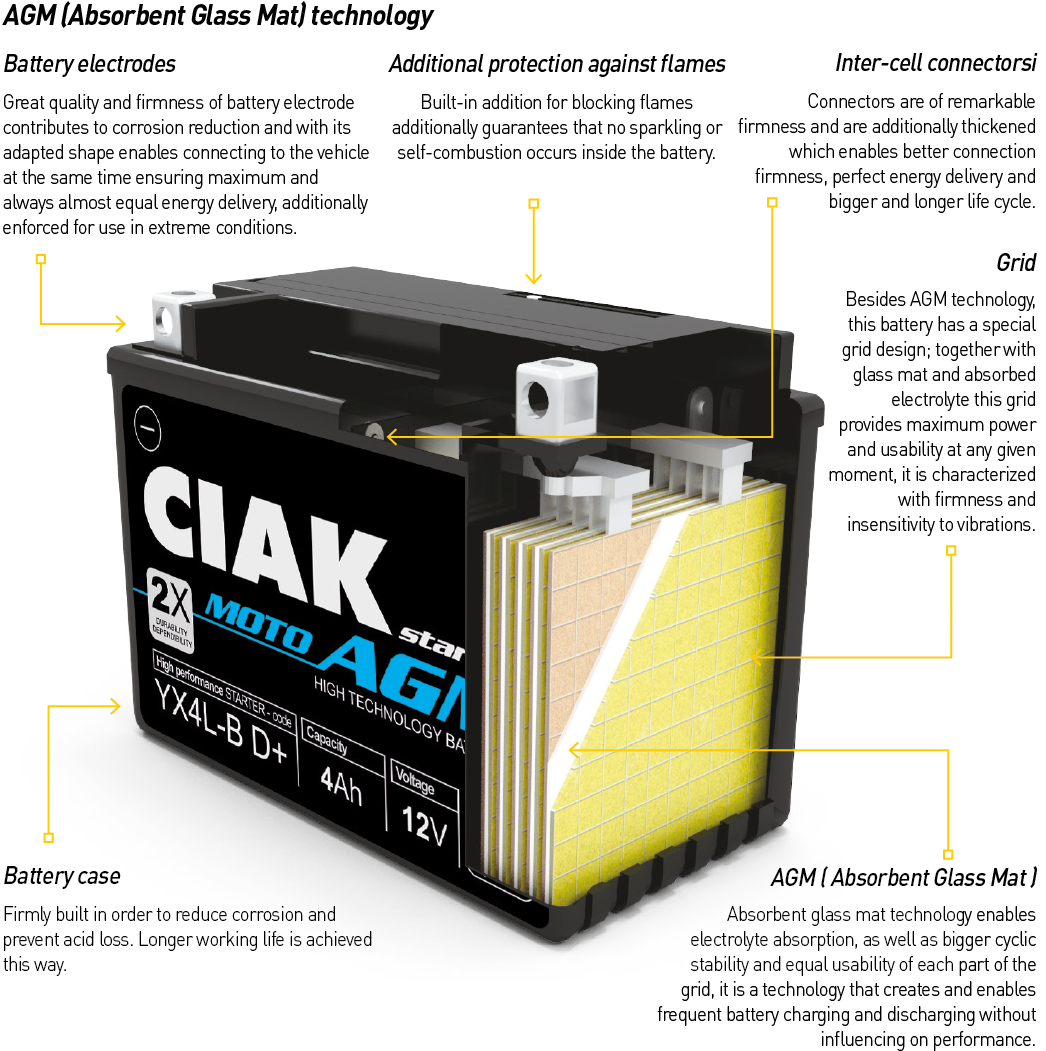

CIAK STARTER MOTO AGM

CIAK STARTER MOTO AGM – FIRST CHOICE FOR MAXIMUM PERFORMANCE

No matter the class or conditions in which you will use your motorcycle, scooter, ATV or any other vehicle that demands this type of battery, CIAK STARTER MOTO AGM is the best choice. Nothing presents a problem for this battery with AGM (Absorbent glass Mat) technology to deliver maximum power and energy at any moment. AGM technology that absorbs liquid electrolyte in special glass mat, enables frequent discharge and use in extreme conditions because of this perfect electrolyte arrangement on the whole cell surface, maximum power is continuously delivered and it does not require any maintenance. CIAK STARTER MOTO AGM battery is characterized with cyclic stability, exceptional vibration resistance and complete security so that no electrolyte leakage and eventual expensive damage on electrics or electronics, located near energy source on most such vehicles, will occur. Long rides with increased number of consumers – serially or not serially built in the vehicle, riding conditions – high or low temperatures, atmospheric conditions – rain, sun or snow, extreme bumps or just comfortable cruising, all that is a natural environment for CIAK STARTER MOTO AGM batteries.

Important

It is recommended to use protective gloves during battery formation for additional protection.CHARGING CIAK STARTER MOTO AGM BATTERY

Prepare the battery

Remove protective foil (it is not necessary to keep it – pay attention to dispose it according to eco standards).

Prepare electrolyte containers

Take out electrolyte containers from plastic wrapping. Remove the lid from the containers and do not pierce protective foil.

Charge battery with electrolyte

Put electrolyte containers vertically above each opening – six sealed openings of each container right above six openings (holes) on the battery lid. Firmly press containers into the openings in order to pierce the seals and the acid will immediately start dripping into each battery cell.

Electrolyte dripping

Do not move containers during battery charge because that can cause leaking outside the battery case. Electrolyte is a very poisonous and aggressive acid that can cause injuries. Complete quantity of electrolyte has to come out of each container. Battery will only in that case be correctly formed and ready to use.

Remove containers

After all electrolyte has poured into the battery, check that all containers are completely empty, if any liquid remained it will pour out if you gently tap the top of the container. After you make sure that all electrolyte has poured out, you can remove the container set.

Close the battery

Each AGM battery comes with associated cap strip and you can exclusively use original strip because any spare strip could cause damage on the battery. It is recommended to wait at least 20 minutes before battery application and installation so that all electrolyte could be absorbed and the battery could be appropriately formed.

BATTERY INSPECTION

![]() Battery Inspection

Battery Inspection

Prior to the first motorcycle ignition or battery charge it is necessary to perform several simple inspections for:

1. Visible electrode, connector or cable damages.

2. Visible corrosion or case cracks.

3. Color change on the case or visible deformations due to overcharge.

4. In CIAK STARTER MOTO models requiring maintenance check the level of electrolyte and, if necessary, add distilled water.

Examination

Examination

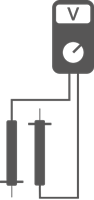

The best way to examine battery state of charge is with a reliable tester that measures voltage, capacity state and starting power – it is recommended to use CIAK 8000 tester with thermal printing.

If you use classic voltmeter, you can read battery state regarding measured voltage from the table.

![]() Maintenance

Maintenance

CIAK STARTER MOTO and CIAK STARTER LAWN TRACTOR batteries should be regularly maintained:

1. Periodical acid level inspection, if necessary add distilled water and strictly adhere to the min and max markers that can be found on the sticker.

2. Maintaining battery and electrode cleanliness in order to prevent self-discharge.

3. Check all cables and connecters to see if they lost contact or are damaged.

4. State of charge.

![]() Warehousing

Warehousing

The most common cause of battery damage is wrong warehousing (nonuse period of a vehicle that uses a battery), i.e. the release of sulfate salts that cause corrosion and permanent damages on lead net. It is very important to properly store the battery so that it is always ready to use and in order to prolong its life cycle.

1. Charge battery before warehousing (before vehicle standstill).

2. Separate negative electrode from the vehicle.

3. In case of battery removal from the vehicle, store the battery in a clean and dry place.

4. During battery standstill period check state of charge once a month and, if necessary, recharge it (use the table).

RECOMMENDATION

Use of charger of verified quality, the advantage is the use of a charger with automatic charging choice which also automatically stops after reaching maximum state of charge in order to avoid permanent battery damage.![]() Charging

Charging

For maximum battery use it is necessary to charge it. Recommended charging current is 10% of the rated capacity in amps.

Example: It is best to charge 12Ah battery with 1,2A charging current.

HR

HR EN

EN